WE DO WHAT WE SAY.

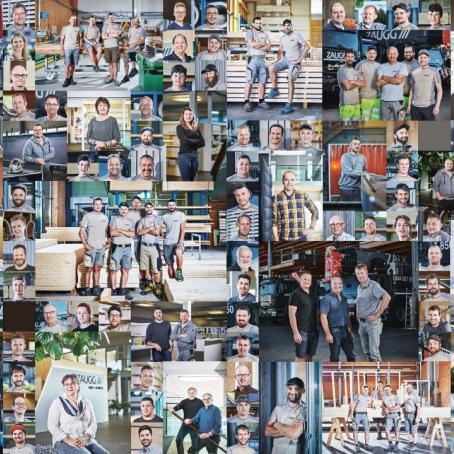

Zaugg is a leading innovator in multiple typologies of timber construction including residential, commercial and industrial. As a vertically integrated enterprise, the company delivers a complete menu of services from design and engineering to mass timber element fabrication, as well as modular mass timber.

Our History

In 1936 the Zaugg family opened for business in Rohrbach, Switzerland, following in the powerful European tradition of timber craftsmanship. Stephan and Martin Zaugg are now the third-generation owners of the business and have carried on the legacy of their parents and grandparents. Zaugg Timber Solutions, or ZTS, is the North American affiliate of the business. ZTS entered the North American marked in 2020, building the first Modular Multifamily Mass Timber Prototype in the US.

Our Values

Zaugg is a values-driven organization focused on its people and its community. Expansion into North America represents for Zaugg an expansion of that community and the opportunity to take part in a new community for whom affordable mass timber is now a growing ambition. Our values include:

We do what we say.

Our integrity is non-negotiable because we do

what we say. We are a reliable and trustworthy partner.

We do more.

We prove ourselves to our customers through

performance and we focus on results. We are flexible and mobile and go

further than others.

We focus on the future.

We are constantly educating ourselves. We focus

on sustainability and innovation.

We look for the best solution.

We actively listen to customers and employees

and question how things are “normally” done. We are innovative, offer

integrated solutions and deliver the highest quality.

We respect other people.

We take responsibility and deal with mistakes

constructively. We are inclusive and do not discriminate on the basis of race,

color, religion, sex, national origin, age, disability, marital status, or

political affiliation.

WE DO MORE.

Since 2020, ZTS has been working to develop a North American manufacturing facility, exploring multiple sites, expanding partnerships, undertaking product development and laying the groundwork to be fully operational by 2026.

We aspire to contribute to North America’s deep aspiration for a sustainable vertical supply chain, from forestry to affordable housing.

For the construction of the new manufacturing facility, we chose to combine traditional timber craftsmanship with modern construction methods to create a sustainable building that is both functional and beautiful.

We deliberately designed and engineered the superstructure as a hybrid of mass timber and steel elements, delivering warmth and beauty while demonstrating how mass timber can be used in industrial construction.

We believe that the ZTS facility will contribute strongly to a broader reduction in construction costs and project completion times across North America.

Opening in April 2026, our first factory, in an existing building, represents the next chapter of ZTS — combining innovation and technology with the values of a family-owned business. With a wide range of high-quality products and a commitment to excellence, we stand miles ahead in shaping the future of sustainable construction.

Experience the skill and precision of our craftsmanship, from timber construction to steelwork, at every step of the process.

THE ONLY MASS TIMBER MODULES MADE IN USA

Get the fastest construction method AND support our local economy.

THE HIGHEST QUALITY TIMBER ELEMENTS

This is the future of construction.

THE MOST COST EFFECTIVE TRADITIONAL GLULAM AND CLT SUPERSTRUCTURES

We deliver affordably and precisely.

WE FOCUS ON THE FUTURE.

Our company operations in Europe follow strict sustainability guidelines which will be mirrored in the ZTS facility wherever possible. We have achieved multiple sustainability certifications for our work over the past 30 years, including the prestigious Swiss Wood Building Certification and the Minergie-P-Eco Certification.

Some of the steps we have taken towards

sustainability over the past few years include:

- Powering 100% of our facilities with renewable energy, including 1 Megawatt of solar capacity and a biomass boiler on site.

- Encouraging our employees to live close to the factory, leading to an average commute time of 20 minutes, thereby reducing transportation pollution.

WE LOOK FOR THE BEST SOLUTION.

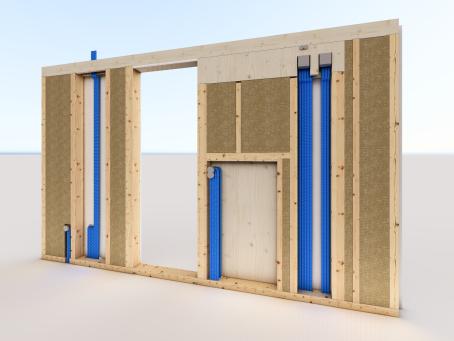

Since 1936, we have manufactured prefabricated buildings from multiple materials with a strong focus on timber. We fabricate to a one millimeter tolerance, exceptional for the North American market.

We have completed over 200 mass timber projects in our Swiss factory over the past thirty years by establishing and following a rigorous set of protocols and organizational methods that deliver predictability of pricing and on-time and on-budget delivery.

Over two decades, we have transitioned from a traditional, craftsman-driven business to a fully automated computer numerical control (CNC) machining enterprise delivering huge time and cost savings to customers. We have achieved these advances while also maintaining a commitment to master-craftsman quality woodwork and rigorous training. This tradition has served to positively impact wages and quality of life for our employees and the greater mass timber ecosystem.

Projects today are designed virtually in three-dimensions and then fabricated and transported at up to 90% completion to job sites, decreasing waste and increasing sustainability at every stage in the process.

WE RESPECT OTHER PEOPLE.

Since 2025 ZTS has employed both North Americans and visiting European trainers in our US operations, focusing on knowledge transfer and training.

Company trainees rotate on a six to twelve month exchange program from and to Europe, expanding on the company’s successful apprenticeship program.

We are launching a system of trade education for young adults, giving them a head start on learning craftsmanship and excellence. The program will last for a minimum of three years with on the job training two to four days per week. This combination of theoretical and practical education is known in Europe as the “dual-system”.

ADVANcED MASS TIMBER PROGRAM

Are you ready to embark on an extraordinary journey of personal and professional growth? We are now offering US citizens the opportunity to step into the exciting world of timber craftsmanship, cultural exchange and adventure. Job training begins in Switzerland and continues with high-quality employment in Oregon.

The Opportunity

We are now seeking four motivated individuals to join our Advanced Mass Timber Training Program. For up to 18 months, you will receive hands-on training in Switzerland in advanced carpentry including mass timber assembly and general building science. During the Program you will be guided by skilled mentors and attend classroom training.

Trainees are paid a living wage from the beginning to the end of the Program and beyond. Upon completion of training, you will return with your colleagues to the US where a job will be waiting for you.

This is more than just a training program. It is an immersive experience in a beautiful and unique country.

Applications

are now open for individuals with carpentry skills.

Apply here

Partnership

The Advanced Mass Timber Training Program has been launched in partnership with the Confederated Tribes and Bands of the Yakama Nation. The Yakama people have inhabited their lands since time immemorial, from the lowlands around the Columbia River to the snow-peaked Cascade Mountains. Today, Yakama Nation is the largest tribe in the Pacific Northwest by both population and land area and is an active participant in the development of a novel advanced mass timber supply chain.

Location

- Classroom training in Biel and Rohrbach, Switzerland

- Practical training in the Swiss factory and on construction sites

- Ongoing training and employment in the US upon return

Language

- English

Prerequisites

- Desire for adventure

- Willingness to relocate for training

- Willingness to work for ZTS in the US for at least one to five years

- Work experience in a related field

- Degree from an accredited college or university or two years of apprenticeship or status as a student

- US citizenship

Program Summary

ZTS will start production of prefabricated mass timber modules and elements in two new factories in Oregon and Montana beginning in 2026 and 2027. The production and assembly of those modules and elements will be carried out by trained specialists from both Switzerland and the US.

In order to train up US specialists, ZTS and its affiliates are now standing up the Advanced Mass Timber Training Program. The Program will train a new cadre of American carpenters in the expert fields of mass timber prefabrication and assembly.

Why choose the Program

- Paid Training: Earn a competitive salary while learning a valuable trade.

- Adventure: Live and work in a stunning Swiss setting, from picturesque villages to breathtaking mountains.

- Cultural Exchange: Dive into Swiss culture, learn new traditions, and bring your American spirit as a bridge between nations.

- Personal Growth: Develop confidence, discipline, and skills that will benefit you for life.

- High-quality Employment: Return to a living wage job in the US after training.

- Ambassadorship: Share your skills, inspire others, and join a growing company that bridges Europe to the US

Training

The Program is designed to provide trainees with the skills and knowledge required for company operations. This includes expertise in machinery, materials, techniques, safety and work processes in the factory and on the job site.

Working in Portland and Bozeman

Upon completion of the Program in Switzerland, trainees will return to work in 2026 in the US. ZTS is developing factories in both Oregon and Montana, with a first opening in Portland in 2026. Trainees will live and thrive in one or both of these dynamic cities with direct access to nature and a growing community of timber experts. ZTS is first and foremost a family of men and women dedicated to the cause of more beautiful and more affordable construction, something desperately needed by both of these incredible destinations.

Apply here

GET IN TOUCH.

Zaugg Timber Solutions Inc.

Building 205, Terminal 2, Port of Portland

3556 NW Front Ave., Portland, OR 97210